Best Industrial Coatings for Structural Steel

When it comes to structural steel, protection is everything. Whether you’re working on a residential deck, commercial infrastructure, or a sprawling industrial plant, applying the right coating ensures your steel lasts decades, not just years. In this guide, we explore the best industrial coatings for structural steel, focusing on use cases in Europe and offering insights for construction workers, DIYers, contractors, and designers.

Why Does Steel Need a Protective Coating?

Steel is strong, but it is vulnerable to corrosion, UV degradation, chemical exposure, and moisture damage. Left untreated, steel will rust, weaken, and ultimately fail. A protective coating:

- Increases longevity and structural safety

- Reduces maintenance and repair costs

- Enhances aesthetics and environmental resistance

- Ensures compliance with European standards (e.g., EN ISO 12944)

Common Applications of Coated Steel

Different coatings suit different applications. Choosing the right one depends on the project environment, desired aesthetics, and lifecycle cost. Typical use cases:

- Bridges & highways (corrosion-resistant epoxy or zinc coatings)

- Coastal buildings (zinc-rich primer with polyurethane topcoat)

- Fencing, posts, and garden hardware (hot-dip galvanized steel)

- Warehouses and factories (powder coating steel for aesthetics and protection)

- Residential pergolas, decks, and carports (galvanising steel with topcoats)

Top Industrial Steel Coating Options in Europe

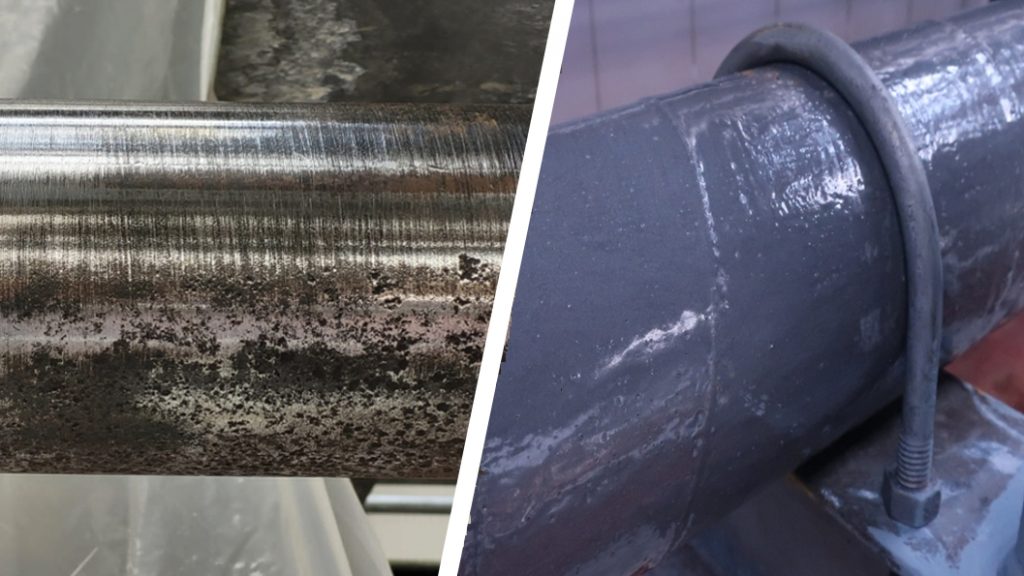

1. Hot-Dip Galvanising Steel

A process in which cleaned steel is immersed in molten zinc (at around 450°C), creating a metallurgically bonded coating. This coating becomes part of the steel, providing comprehensive protection from environmental elements.

Best for: Outdoor structural steel, garden hardware, fencing, scaffolding.

Advantages:

- Long-term corrosion protection (up to 50 years in rural areas)

- Tough, abrasion-resistant finish

- Low maintenance with no need for frequent recoating

- Cost-effective for mass production

- Complies with ISO 1461, widely adopted across Europe

2. Epoxy Coatings

Applied as a liquid or powder, epoxy coatings cure into a hard, chemical-resistant barrier. Typically used as a base or mid-coat in multi-layer systems.

Best for: Chemical plants, manufacturing units, submerged steel, basement reinforcements

Advantages:

- High chemical, moisture, and abrasion resistance

- Excellent adhesion to properly prepared steel

- Service life up to 20–30 years with topcoats

- Compatible with both galvanized and bare steel

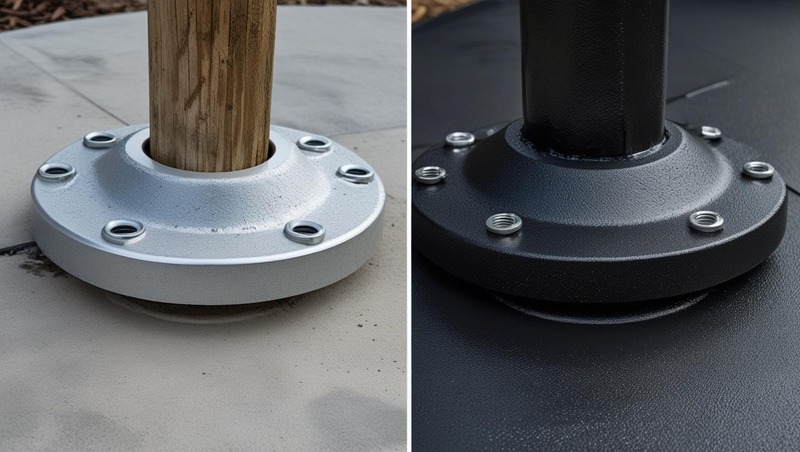

4. Powder Coating Steel

An eco-friendly coating applied as a free-flowing, dry powder using electrostatic spray, then cured under heat. It provides both protection and decorative finish.

Best for: Handrails, gates, steel furniture, posts, urban fixtures

Advantages:

- No solvents, low environmental impact (VOC-free)

- Vibrant, customizable colours with a smooth finish

- Resistant to chipping, scratching, and fading

- Typically lasts 15–20 years outdoors

5. Polyurethane Coatings

Used as a topcoat in high-performance systems, polyurethane provides excellent UV resistance and colour retention. Applied over zinc primers or epoxy base coats.

Best for: Exteriors, rooftops, façades, bridges

Advantages:

- Exceptional gloss and finish durability

- Prolongs life of underlying coatings

- Lifespan of 10–20 years depending on exposure

6. Intumescent Coatings

A passive fire protection coating that expands when exposed to high heat, forming an insulating barrier that slows heat transfer to the steel.

Best for: High-rise buildings, schools, hospitals

Advantages:

- Discreet fireproofing option for exposed steel

- Maintains aesthetic while meeting safety codes

- Lifespan of up to 25 years with proper maintenance

Financial Benefits of Steel Coating

Investing in protective coatings significantly reduces long-term costs:

- Prevents structural failure and premature replacements

- Minimises repair downtime

- Ensures insurance compliance and project safety certifications

- Enhances property resale value

A small upfront cost in coating can save thousands in repairs and replacements later.

____________________________________________________________________________________________________

FAQs

Q1: What are the different types of steel coatings?

The most common include hot-dip galvanising, zinc-rich primers, epoxy coatings, polyurethane topcoats, powder coating, and intumescent fireproofing.

Q2: Why does steel need a protective coating?

To prevent corrosion, improve durability, comply with safety regulations, and enhance aesthetic appeal, especially in outdoor or industrial environments.

Q3: What is the most durable coating for steel?

Hot-dip galvanising combined with a polyurethane topcoat offers one of the most durable and long-lasting solutions, especially in corrosive environments.

Whether you’re installing a steel pergola in a London garden, erecting warehouse structures in Germany, or building coastal infrastructure in Spain, choosing the right steel coating can make or break the project. For optimal results, consult with your coating provider and ensure your solution is compliant with EN ISO 12944 standards.

Protect your investment. Coat it right.

Author