Galvanized vs Powder Coated Steel: What European Builders Need to Know Now

In today’s high spec construction landscape, coating choice is not cosmetic but strategic.

Whether you’re pricing out beams for a coastal infrastructure project in Cornwall or stocking structural steel angles for a modular housing rollout in Berlin, your coating spec directly impacts lifespan, cost of ownership, and compliance.

At GKG Industry, we’ve spent two decades in the trenches with builders, procurement heads, and engineering consultants. Here’s the real world breakdown on galvanized steel vs powder coated steel- no fluff, just insight.

🛠️ First, Know the Game: Barrier vs Sacrificial Protection

Here’s the technical core:

- Galvanized steel relies on sacrificial corrosion protection. Zinc bonds to the steel and corrodes first, taking the damage before your structure does.

- Powder coating works as a barrier layer. If the coating is breached, corrosion starts to set in fast.

This makes galvanization a go-to for scaffolding, bridges, and utility structures- all the exposed builds that need to survive frost, rain, salt, and time.

🌧️ Wet Weather? Galvanize It

From coastal Wales to the Port of Rotterdam, we’re seeing more specs call for durability in marine grade or high humidity zones.

- Hot dip galvanizing delivers a dense zinc layer that locks in protection and keeps water from creeping in.

- For garden hardware or light structural components exposed to seasonal elements, epoxy powder coating (yes, we do that too) gives both color and performance, but only when surface treatment is done right.

Quick tip: If it’s near the sea or in a fog prone area, galvanize it. Every time.

🧪 Thickness, Lifespan and Repairability

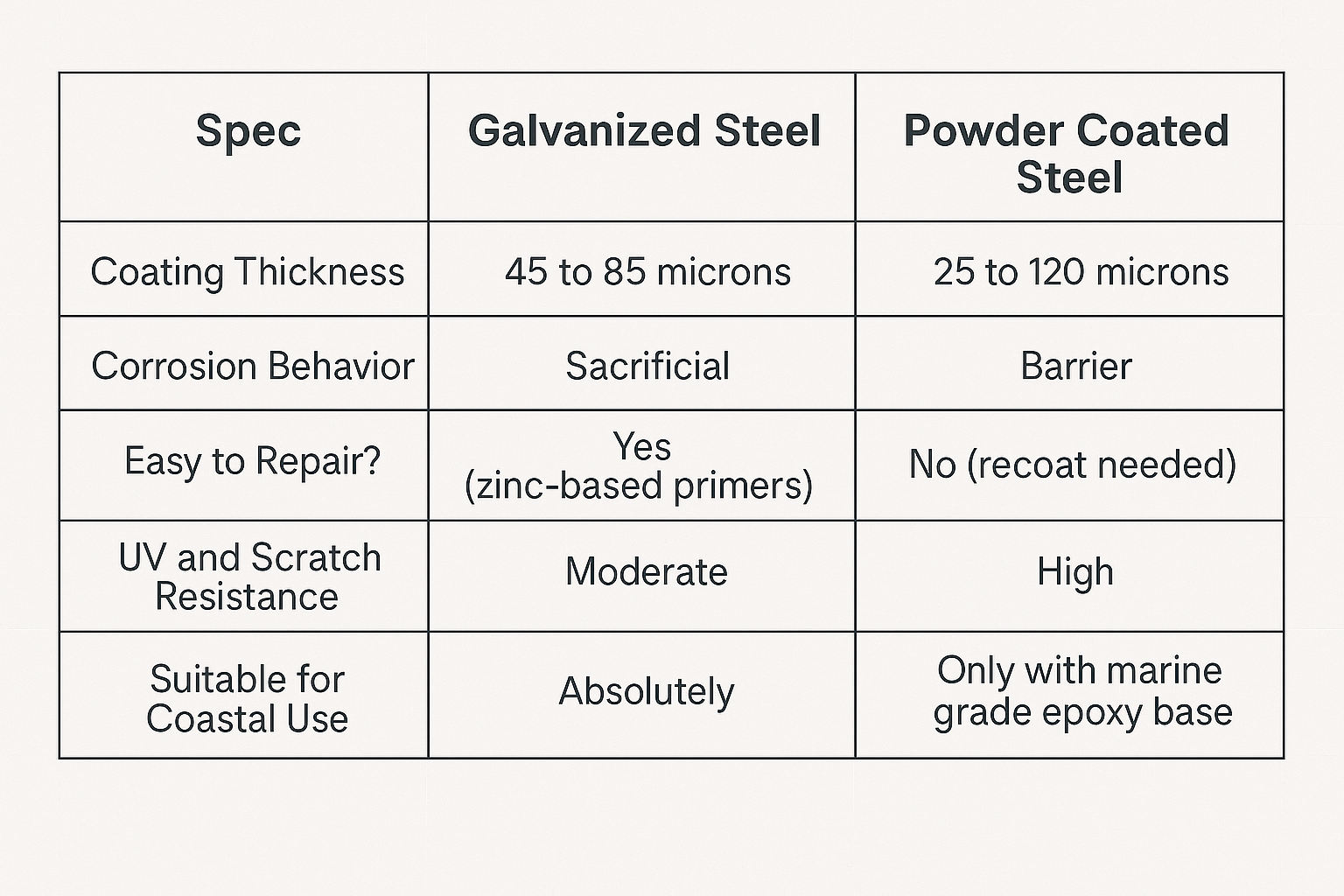

Want the numbers? Here’s how the specs compare:

Galvanizing self heals at minor damage points. The zinc keeps protecting. Powder coating looks sharp but once it chips, corrosion begins.

🧱 Visual Appeal vs Rugged Durability

Yes, powder coated steel looks sleek. RAL matched, glossy finishes, even texturing. Great for visible fixtures, gates, or handrails.

But if you’re installing scaffold systems, formwork supports, or load bearing channels, post anchors, and ground plates that disappear inside concrete, function takes priority over finish.

And there’s a growing trend in residential developments and retail architecture toward duplex coating, i.e., galvanized steel topped with powder. It delivers the best of both. But it comes at a price.

🧰 The Procurement Mindset: Focus on Lifecycle Wins

Steel is no longer just a material purchase. It is an integral part of your project strategy.

Questions worth asking:

- What is the total lifecycle value of this coated product in your project?

- Will compliance with REACH or EN ISO 1461 come into play in five years?

- Can your team justify the cost per square meter when comparing maintenance cycles?

Construction leaders across Europe and the UK are asking these exact questions. The trend is moving toward hot dip galvanized structural components, with powder coating reserved for high touch or design driven applications.

🧭 What We’re Seeing in the Market

- Germany: Warehouse developers moving fully into galvanized rebars and columns

- Netherlands: Coastal projects pushing for duplex coating on exposed steel

- UK: Retail stockists expand their powder coated fencing range ahead of spring

- France: Public sector bids now specify EN ISO 12944 corrosion categories, making galvanized steel the safer route

“In today’s procurement cycle, steel buyers are sourcing predictability, compliance, and long term value,” says Vikram Goenka, Managing Director at GKG Industry. “That’s why knowing your coatings is no longer optional, it’s essential.”

The Coating Is Strategic, Not Cosmetic

If you’re working in damp regions, coastal zones, or long term infrastructure builds, galvanizing should be your default.

If your steel is part of the visible spec, brand aligned, or in dry interiors, powder coating will give it an edge.

And if you’re a wholesaler, specifier, or OEM across Europe or the UK, stay tuned. GKG Industry is rolling out one of the most durability focused, Euro compliant structural steel portfolios on the market. Quietly, consistently, and with purpose.

Want more insights like this? We share fresh, steel smart thinking more often. Stay close. You’ll be ahead of the curve before the curve even shifts.

Author